Today I brewed up 10 gallons of Pale Ale. Since it's a work day I decided to try to start brewing early, I mean really, really early. I lit the burner at 4:11 AM and mashed in at 5:19 AM. This is by far the best time of day to brew!

Here's the recipe for today's brew session:

Sierra Nevada Clone

10-A American Pale Ale

Size: 11 gal

Efficiency: 70.0% Attenuation: 75.0%

Calories: 189.99 kcal per 12.0 fl oz

Original Gravity: 1.057 (1.045 - 1.060)

Terminal Gravity: 1.014 (1.010 - 1.015)

Color: 13.64 (5.0 - 14.0)

Alcohol: 5.61% (4.5% - 6.2%)

Bitterness: 36.5 (30.0 - 45.0)

Ingredients:

23.0 lb Pale Ale Malt

2 lb Crystal Malt 60°L

1.0 lb 2-Row Carapils® Malt

1 oz Chinook (13.0%) - added during boil, boiled 60.0 min

1.0 oz Perle (5.5%) - added during boil, boiled 30.0 min

2.0 oz Cascade (5.6%) - added during boil, boiled 10.0 min

4.0 oz Cascade (5.6%) - added during boil, boiled 0.0 min

2.0 oz Cascade (5.6%) - added to the primary fermenter after fermentation is complete (1st carboy)

2.0 oz Amarillo (5.6%) - added to the primary fermenter after fermentation is complete (2nd carboy)

2.0 ea White Labs WLP001 California Ale

Here are a few pics from the day:

Lighting the burner at 4 AM!

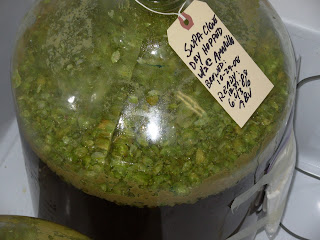

Coffee and hops. The breakfast of champions!

Lighting the burner at 4 AM!

Lighting the burner at 4 AM! Coffee and hops. The breakfast of champions!

Coffee and hops. The breakfast of champions!